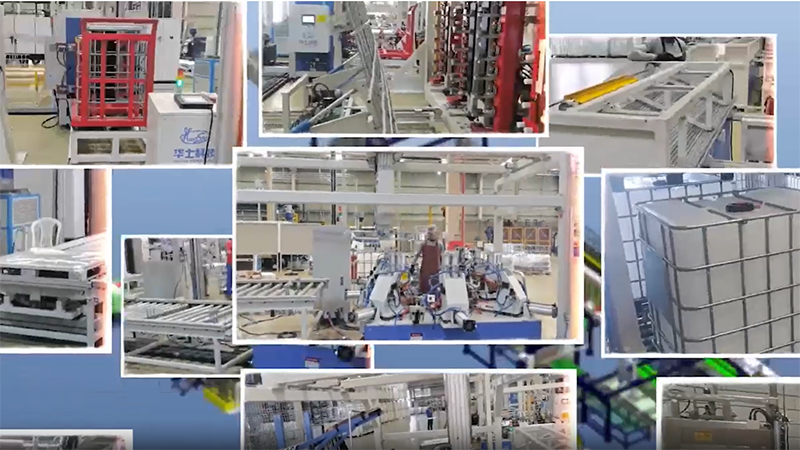

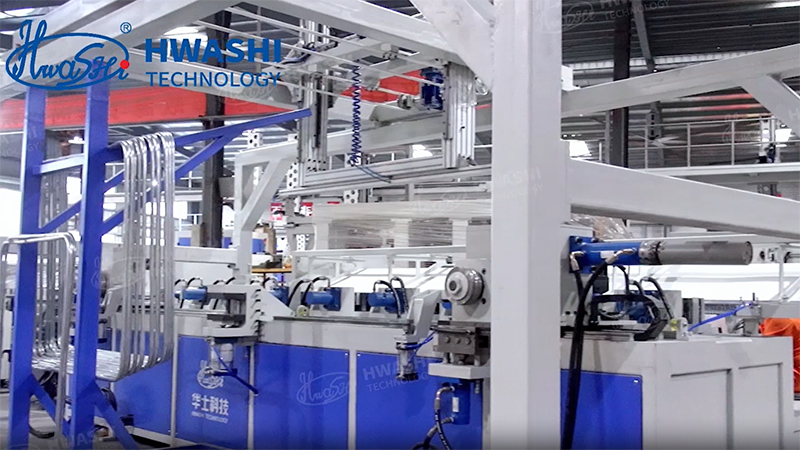

IBC Tote Cage Welding Line

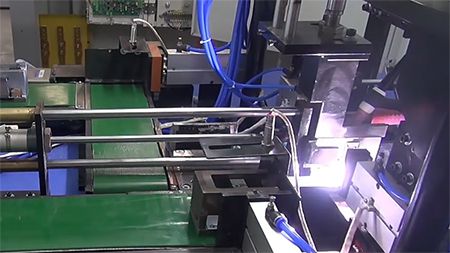

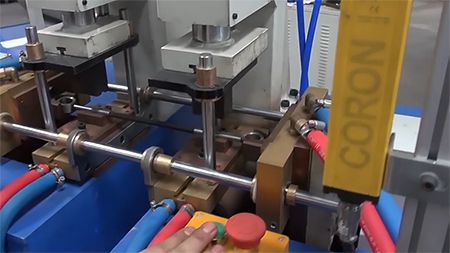

Our IBC tote cage welding line provides an automated solution professionally crafted for the seamless production of 1000L IBC tote cages. This IBC tank production line features high precision, handling tasks from frame material cutting to welding, bending, and punching with utmost accuracy.

Designed for operational efficiency, this automated welding system effortlessly executes tasks such as valve welding into the IBC container and comprehensive leakage detection. Moreover, it ensures a streamlined end-to-end process by automatically assembling and palletizing both the frame and IBC (Intermediate Bulk Container) tote.

Get in Touch

Videos

-

Company Profile

Company Profile

-

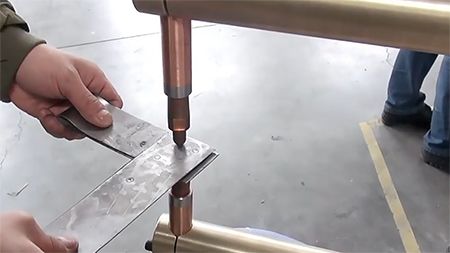

Capacitor Discharge Spot Welder

Capacitor Discharge Spot Welder

-

Mid-Frequency DC Inverter Spot Welder

Mid-Frequency DC Inverter Spot Welder

-

AC Pulse Spot Welder

AC Pulse Spot Welder

-

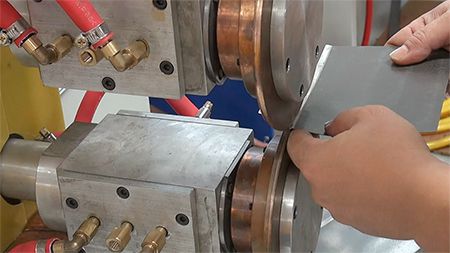

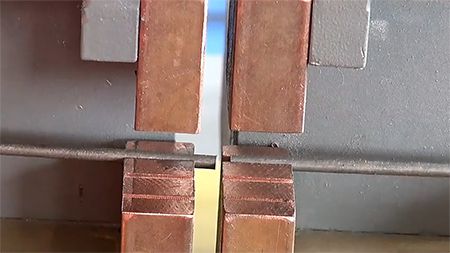

Resistance Seam Welding Machine

Resistance Seam Welding Machine

-

Resistance Butt Welding Machine

Resistance Butt Welding Machine

-

6-Axis Robotic Arm

6-Axis Robotic Arm

-

Palletizing Robot

Palletizing Robot

-

IBC Tote Cage Welding Line

IBC Tote Cage Welding Line

-

Refrigerator Condenser Welding Line

Refrigerator Condenser Welding Line

-

Mesh Basket & Drawer Welding Line

Mesh Basket & Drawer Welding Line

-

Wire Shelf & Rack Welding Line

Wire Shelf & Rack Welding Line

-

Stainless Steel Sink Welding Line

Stainless Steel Sink Welding Line

-

Robotic Welding Cells

Robotic Welding Cells

-

Customer Showcase

Customer Showcase

-

FX28 Automatic Straight Seam Welded Pipe Production Line

FX28 Automatic Straight Seam Welded Pipe Production Line

-

Automatic IBC Long Tube Pressing and Forming Machine

Automatic IBC Long Tube Pressing and Forming Machine

-

Automatic IBC Short Tube Pressing and Forming Machine

Automatic IBC Short Tube Pressing and Forming Machine

-

Automatic IBC Base Frame Tube Bending Machine

Automatic IBC Base Frame Tube Bending Machine

-

IBC Tank Blow Molding Machine

IBC Tank Blow Molding Machine

-

Sheet Metal Box

Sheet Metal Box

-

Low-Voltage Electrical Components

Low-Voltage Electrical Components

-

Auto Parts

Auto Parts

-

Metal Hardware

Metal Hardware