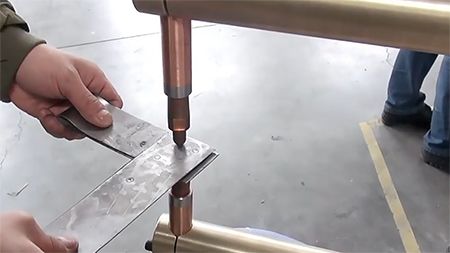

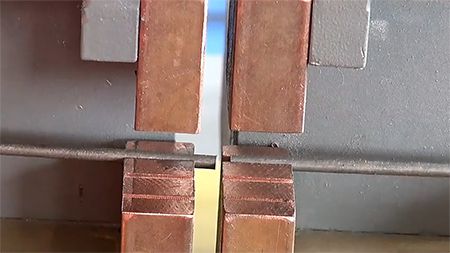

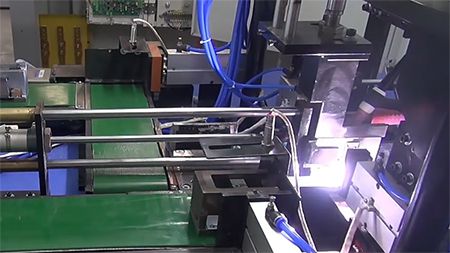

Seam welding is a resistance welding process for joining metal sheets in continuous, leak tight seam joints by directly applying opposing forces with electrodes consisting of rotary wheels. The seam of the resistance seam welding machine consists of individual weld spots. The formation process of each weld spot involves three stages: pressure application, heating and melting, and cooling and crystallization, similar to spot welding. However, there are significant differences between seam welding and spot welding. Due to the inevitable occurrence of diversion, the distribution of the electrical and thermal fields in the welding area possesses its own characteristics.

View More-

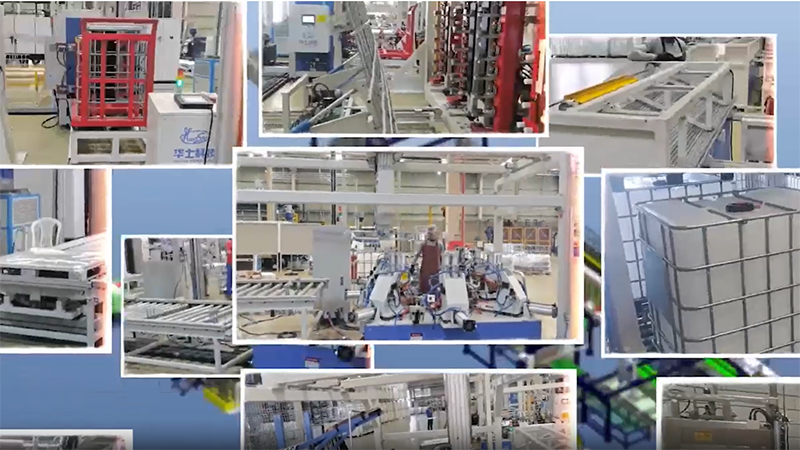

Company Profile

Company Profile

-

Capacitor Discharge Spot Welder

Capacitor Discharge Spot Welder

-

Mid-Frequency DC Inverter Spot Welder

Mid-Frequency DC Inverter Spot Welder

-

AC Pulse Spot Welder

AC Pulse Spot Welder

-

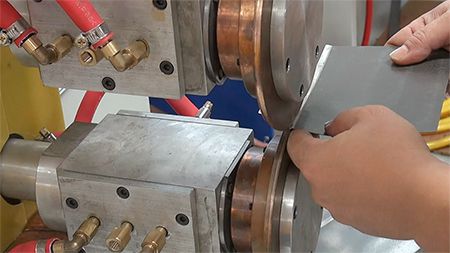

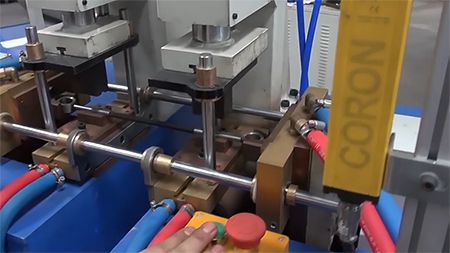

Resistance Seam Welding Machine

Resistance Seam Welding Machine

-

Resistance Butt Welding Machine

Resistance Butt Welding Machine

-

6-Axis Robotic Arm

6-Axis Robotic Arm

-

Palletizing Robot

Palletizing Robot

-

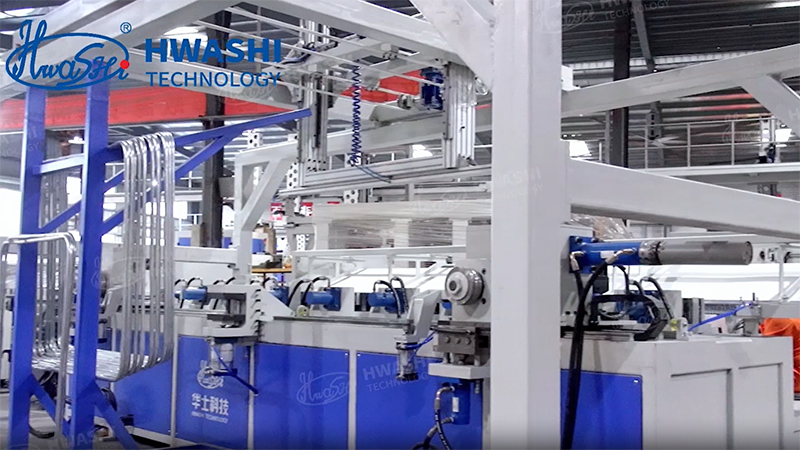

IBC Tote Cage Welding Line

IBC Tote Cage Welding Line

-

Refrigerator Condenser Welding Line

Refrigerator Condenser Welding Line

-

Mesh Basket & Drawer Welding Line

Mesh Basket & Drawer Welding Line

-

Wire Shelf & Rack Welding Line

Wire Shelf & Rack Welding Line

-

Stainless Steel Sink Welding Line

Stainless Steel Sink Welding Line

-

Robotic Welding Cells

Robotic Welding Cells

-

Customer Showcase

Customer Showcase

-

FX28 Automatic Straight Seam Welded Pipe Production Line

FX28 Automatic Straight Seam Welded Pipe Production Line

-

Automatic IBC Long Tube Pressing and Forming Machine

Automatic IBC Long Tube Pressing and Forming Machine

-

Automatic IBC Short Tube Pressing and Forming Machine

Automatic IBC Short Tube Pressing and Forming Machine

-

Automatic IBC Base Frame Tube Bending Machine

Automatic IBC Base Frame Tube Bending Machine

-

IBC Tank Blow Molding Machine

IBC Tank Blow Molding Machine

-

Sheet Metal Box

Sheet Metal Box

-

Low-Voltage Electrical Components

Low-Voltage Electrical Components

-

Auto Parts

Auto Parts

-

Metal Hardware

Metal Hardware