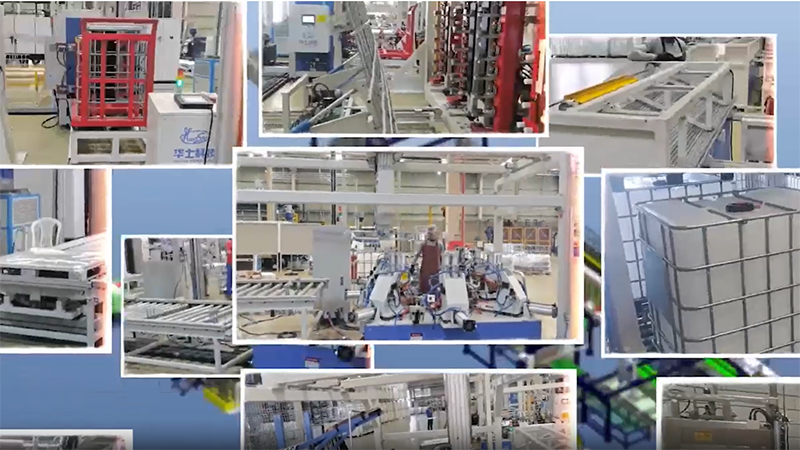

Our IBC tote cage welding line provides an automated solution professionally crafted for the automatic production of 1000L IBC tote cages. This IBC tank production line features high precision, handling tasks from frame material cutting to welding, bending, and punching with utmost accuracy.

Designed for operational efficiency, this automated welding system effortlessly executes tasks such as valve welding into the IBC container and comprehensive leakage detection. Moreover, it ensures a streamlined end-to-end process by automatically assembling and palletizing both the frame and IBC (Intermediate Bulk Container) tote.

Tailored to accommodate various operational scenarios, our IBC tank production line boasts flexibility, requiring as few as 8 personnel for optimal functionality, contingent upon the chosen configuration. You can enhance your manufacturing capabilities with a rapid production time ranging from 60 to 125 seconds per unit. We also provide services to customize the equipment configuration to align with the unique efficiency requirements of your operation.

The welding power supply design allows for the simultaneous welding of six welding heads. It features a single-side double-layer feeder, where one side is dedicated to welding while the other for loading material, enabling a continuous work cycle. Easy unloading is supported by an automatic unloading mechanical arm.

The machine frame is integrally processed, which guarantees precise bending, stable and efficient operation, with the capability to bend one steel cage every 20-25 seconds. The versatility to bend different tubes is easily accomplished by changing the mold, and the mold can be changed effortlessly.

High alignment accuracy, locking fastness, stable and efficient operation.

The integrally processed machine frame ensures high precision and stable, efficient operation. The ability to punch different pipes is easily accomplished by changing the mold block, with a straightforward and effortless mold replacement process.

The comprehensive automated production line showcases remarkable efficiency by seamlessly executing the bending, locking, and punching processes for each steel cage in mere 40 seconds.

In accordance with the IBC specifications for the pallet frame welding positions, the configuration incorporates seven welding stations to precisely fulfill the seven welding position requirements for the pallet frame.

The production line encompasses a series of essential processes, including valve welding, container leakage testing, automatic assembly of both the container and steel cage, pull rod installation, and the final step of automated palletizing. This integrated workflow ensures a comprehensive and systematic approach to manufacturing, covering crucial aspects of assembly and quality control.

This equipment conducts a vibration simulation test in a vertical direction through a motor-driven platform. It is capable of simulating environments with up and down vibrations, accommodating simulations of IBC tote weighing up to two tons with a maximum load capacity of 3 tons.

We tailored a totally automatic IBC cage assembly line specifically for our Brazilian customer. The system comprises of a complete assembly and stacking machine, a cage welding machine, a clinching machine, a hole punching machine, pallet welding machine, valve screwing machine, leakage testing equipment. With an impressive output rate of 50 seconds per piece, the entire line requires only 7–8 operators, ensuring high efficiency and productivity.

If you have any business inquiries or product questions, please feel free to contact us.

With over 20 years of combined experience in the field of resistance welding machines and automatic welding systems, we know what global manufacturers need to stand out in their competitive market.

View More